Scaletron’s Model 4042ECO™ Spill Containment Scales offer many advantages that our competitors can’t match!

Scaletron is the only company to offer a complete line of spill containment scales with multiple base sizes and containment capacities. From drums to tanks to IBC totes, our scales are equipped to handle a wide range of chemical weighing applications.

Scaletron’s Economical Spill Containment Scales will accurately weigh a variety of containers including drums, tanks and IBC totes up to 26″ x 26″. In addition, custom sizes are available.

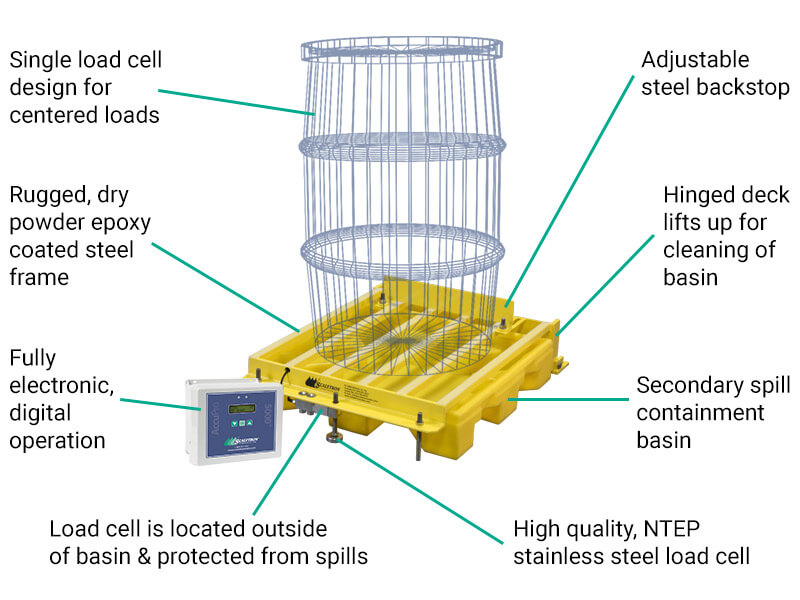

The Model 4042ECO Scales are designed for weighing corrosive materials and feature a rugged steel base, protected by a corrosion resistant finish plus stainless steel load cells and hardware – all backed by a five year warranty. Typical chemicals being weighed are highly corrosive and include chemicals such as alum, ammonia, caustic, fluoride, phosphate, polymers, sodium aluminate, sodium bisulfate, sodium hydroxide, sodium hypochlorite and other liquids or powders.

A complete line of indicators and advanced process controllers are available to meet a wide variety of application requirements including weighing, dosing and batching.

An economical single load cell design requires loads to be centered on the scale while the adjustable backstop with drum size guide makes centering easy. Ideal for frequent on/off loading of containers.

Scaletron’s innovative design features a scale base with a separate molded plastic spill containment basin. The load cell is mounted to the scale base outside of the containment basin and out of contact with corrosive chemicals. Other designs on the market have the load cells and wiring mounted inside the spill containment tank, where they are fully exposed to even the slightest spill or splash from the corrosive chemical being monitored. Just one spill can cause the load cells and wiring to corrode requiring expensive maintenance and replacement of the load cells.

Increased reliability means, lower costs. With Scaletron’s scales, cost savings are realized by eliminating the facility downtime that typically occurs after a chemical spill in order to replace damaged load cells and wiring. Facilities will log less down time and more hours in operation by simply using the Scaletron Model 4042ECO Spill Containment Scale in place of another manufacturer’s. Over the long run our scales save money.

An optional expansion bladder provides dramatically increased spill containment capacity in the event of a major spill or leak.

Ideal for industrial and chemical process applications, the spill alarm sensor utilizes a phototransistor to detect spills and activate a relay switch. The relay may be used to trigger a light or an audible alarm. Additionally, the relay is readily integrated via PLC with other equipment or a central monitoring station to facilitate automatic shutdowns, lockouts and other safety procedures.

Scaletron’s indicators and process controllers offer a built-in 4-20 mA analog output that can be used in conjunction with a scale indicator. The 4-20 mA output allows Scaletron’s scales to be integrated via PLC with other local equipment or SCADA systems at a central monitoring station. Ideal for remote installations, it reduces the need to visit the site where the scale is located.

Prior to shipment, Scaletron custom calibrates and tests all equipment to customers’ exact specifications and application requirements. Scale indicators, depending on the model, can be calibrated in various units of weight or volume including pounds, kilograms, gallons and liters.

With so many advantages it is easy to see why Scaletron’s Model 4042ECO™ Spill Containment Scales are the best choice for all types of water treatment and chemical processing facilities. Contact us today to find out how Scaletron scales can improve your operations.